Industry 4.0

Who it's for:

Electrical / Electronics engineers, technicians, control professionals.

Students in EEE / ECE / Instrumentation/MCA/BTech looking to specialize.

Why it matters:

High demand for PLC + SCADA expertise in industries like manufacturing, power, and process control.

Delivery Mode:

60–80 hrs instructor-led (online or classroom).

Hands-on lab sessions using Siemens, Allen-Bradley, Delta, ABB etc.

Inside Center – Syllabus Highlights

PLC Fundamentals

PLC architecture, I/O wiring, scan cycle, troubleshooting.

Devices and interfacing: digital/analog I/O, relays, sensors.

Programming techniques: Ladder logic, timers/counters, flags, advanced instructions.

PLC Programming Practice

Configuring modules (Siemens S7, Allen-Bradley Micrologix, Mitsubishi, ABB).

Real-world tasks: arithmetic operations, PID control, data handling.

SCADA & HMI Design

SCADA system architecture, tag database, alarm management.

HMI / SCADA tools: Wonderware, WinCC, RSView, Citect, Ignition.

Screens, trends, historical logging, scripting.

Network & Communication Protocols

Industrial standards: Modbus (RTU/TCP), Profibus, Profinet, Ethernet/IP, OPC, MQTT.

Integration Projects

PLC–SCADA interfacing, live industrial processes simulation.

Commissioning, fault diagnosis, VFD & servo control interface.

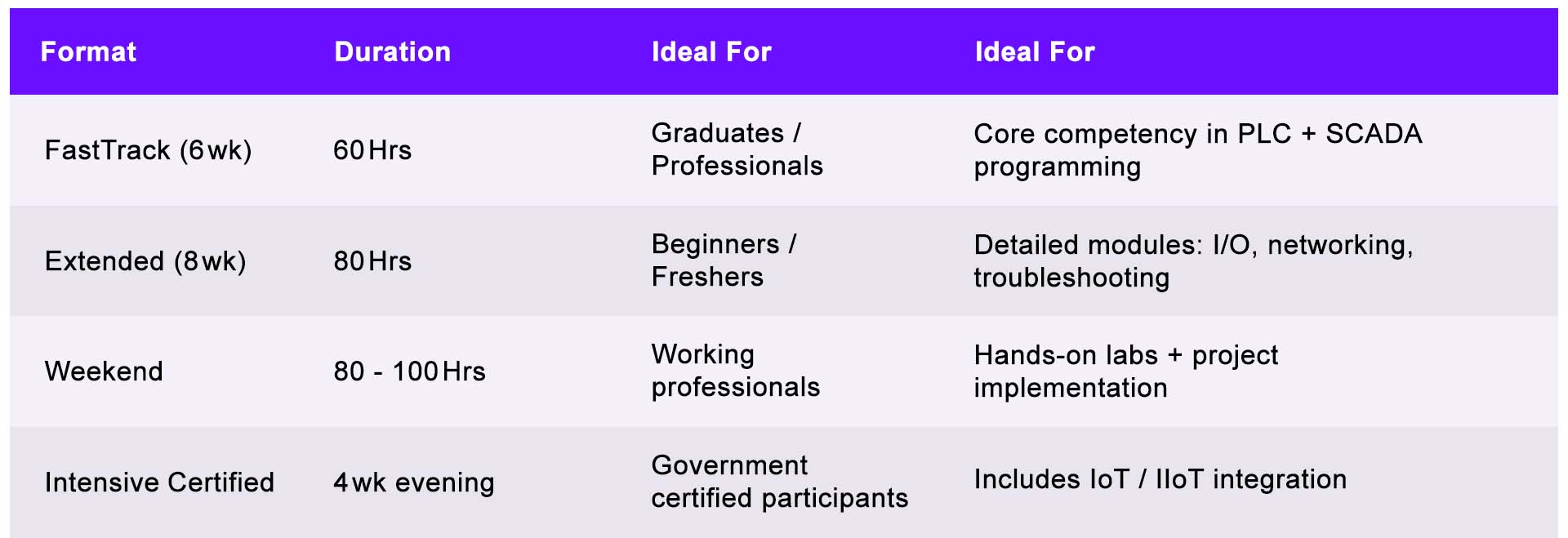

Inside Right – Course Formats

Who Should Enroll?

Engineers / Technicians – Learn PLCs, SCADA setup and plant automation.

Maintenance Professionals – Troubleshoot ladder logic and HMI systems.

Students / Career Changers – Enter automation domain with practical skills.

IT Network Staff – Understand industrial protocols and secure integration.

Capstone & Certification

Live Capstone Project: Simulate a control system (e.g., conveyor belt, tank process) integrating PLC, SCADA, HMI, networking.

Certification: Receive a course certificate supported by placement support.

Contact Us

4th Floor, Oberle Towers,

Balmatta, Mangaluru.

mlr@varmatrix.com

+91 93809 71845

0824 4251407

0824 4261407